Severe Plastic Deformation

Severe plastic deformation (SPD) processes are a group of unconventional thermomechanical processes characterized by imposing very high plastic deformations on the material, typically exceeding 100%. The mechanical properties of metallic alloys subjected to SPD can be significantly modified, reflecting the significant microstructural alterations generated by the process. Generally, SPD processes increase the density of defects in the microstructure, reduce grain size, and generate well-defined crystallographic textures. In some alloys, it is possible to obtain nanocrystalline structures through SPD, with grain sizes below 100 nm.

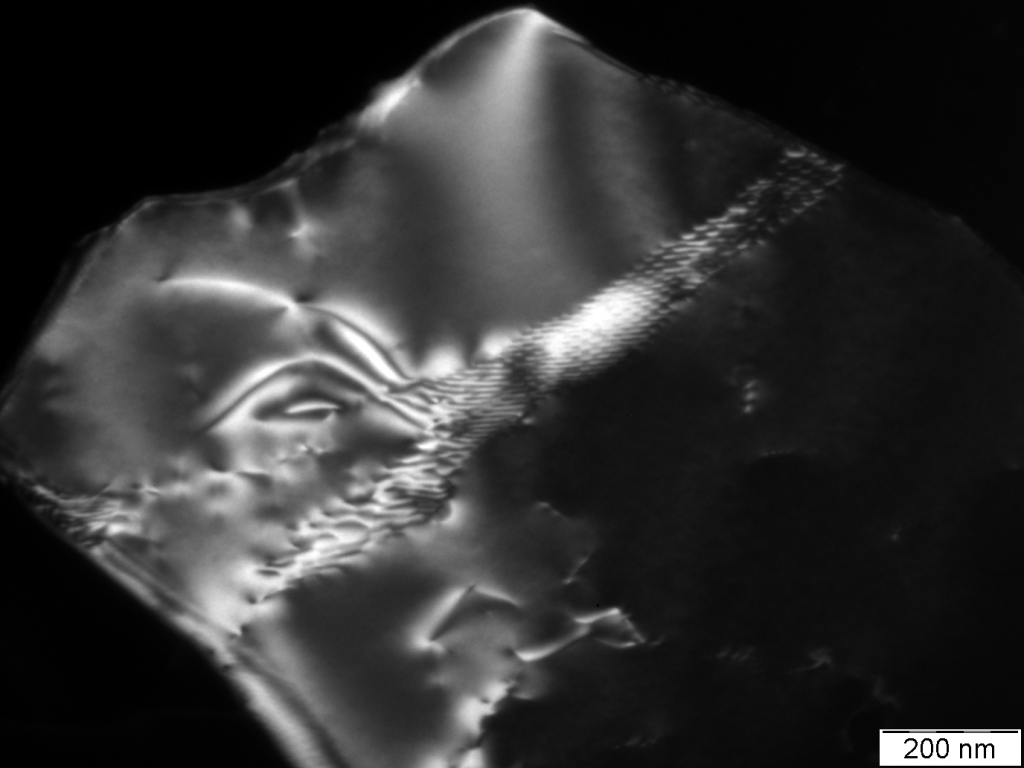

Figure 1 – Grain subdivision process through accumulation of dislocations in Al subjected to severe plastic deformation. Dark field (TEM).

Macroscopically, materials subjected to SPD typically exhibit a significant increase in plastic deformation stress, lower strain hardening rate, and strongly anisotropic behavior. For example, it has been reported in the literature that the plastic deformation stress of Al subjected to SPD can be more than 3 times higher than the plastic deformation stress of annealed Al. However, the strain hardening rate of Al subjected to SPD can take negative values, meaning that the plastic deformation stress decreases with increasing deformation.

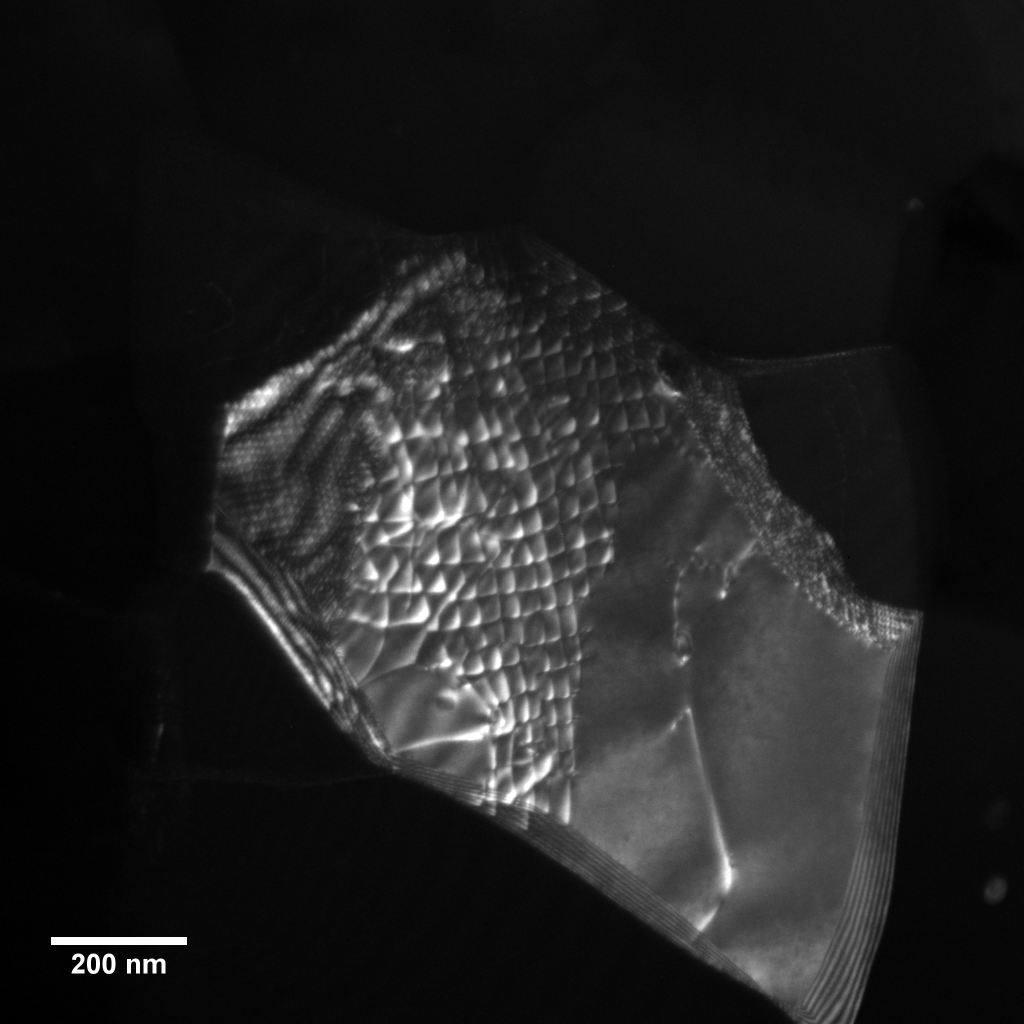

Figure 2 – Al grain divided into subgrains and/or cells, with similar crystallographic orientation. Dark field (TEM).

SPD processes also affect precipitation: depending on the initial state and chemical composition of the alloy, plastic deformation can favor both precipitation and dissolution of existing precipitates. To date, SPD processes - and the associated metallurgical phenomena - are one of the most important frontiers of knowledge in Mechanical Metallurgy, with possible industrial applications: some SPD processes can be adapted to production lines, aiming to adjust the mechanical behavior of metallic alloys.

Figure 3 – Dislocation network in an Al grain. Dark field (TEM).

In this research line, we use thermomechanical processes to prepare samples (specific sequences of deformation processes and heat treatments) and materials characterization techniques such as: tensile tests, X-ray diffraction, and transmission electron microscopy.

External Collaborators:

Paulo Cetlin (Dept. Mech. Eng. - UFMG – Brazil)

Related Publications:

FLAUSINO, P. C. A., NASSIF, M. E. L., DE CASTRO BUBANI, F., PEREIRA, P.H.R., AGUILAR, M. T. P., CETLIN, P. R.. Microstructural evolution and mechanical behavior of copper processed by low strain amplitude multi-directional forging, Materials Science and Engineering A 756, 474-483, 2019. http://dx.doi.org/10.1016/j.msea.2019.04.075

DE FARIA, C. B., SILVA, N. G. A., DE CASTRO BUBANI, F., BALZUWEIT, K., AGUILAR, M. T. P., CETLIN, P. R.. Microstructural evolution in the low strain amplitude multi-axial compression (LSA-MAC) after equal channel angular pressing (ECAP) of aluminum, Materials Letters 227, 149-153, 2018. http://dx.doi.org/10.1016/j.matlet.2018.05.054