Phase Stability in Shape Memory Alloys of Cu

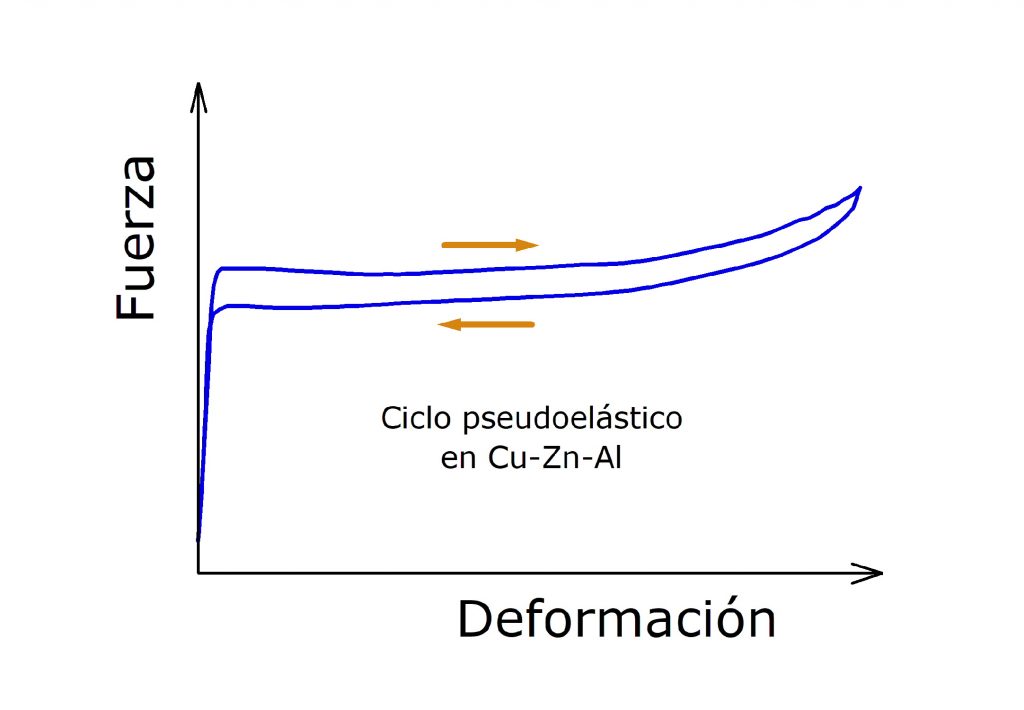

The technological applications of shape memory materials depend largely on the relative stability of the phases involved in the martensitic transformation, which is responsible for the memory and pseudoelasticity effects. Basically, the shape memory effect is the material’s ability to achieve two markedly different configurations by simply changing the temperature. This effect can be made reversible with proper training. On the other hand, pseudoelasticity is the ability to elongate or shorten by up to 10% of its initial length under the influence of an external force.

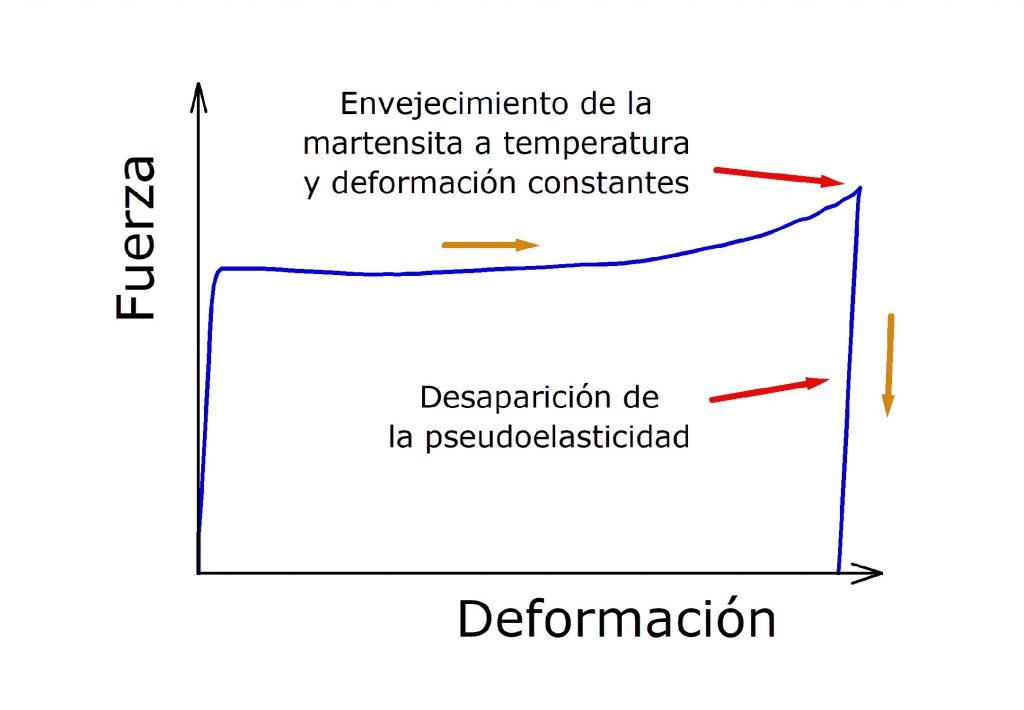

With a change in the relative stability of the phases, the temperatures and stresses of the martensitic transformation are modified. In particular, it has been observed that certain aging conditions of Cu alloys can cause shifts of hundreds of degrees in these transformation temperatures. This latter phenomenon, known as “stabilization”, can then prevent certain technological applications based on shape memory or pseudoelasticity. The device would reach the conditions where the change should occur according to the design, but the material still does not feel the thermodynamic force it needs to make it happen.

To understand and control stabilization, both experimental work and simulations are necessary. Experimental work involves analyzing the effect of heat treatments and aging on the characteristics of the martensitic transformation. Simulations attempt to elucidate the possible mechanisms of atomic diffusion that, by changing the arrangement of atoms within the crystal structure, cause the relative stability of the phases to change.