MMFs used as linear actuators

Conducting in-situ mechanical tests allows for the observation of the sample using various instruments (optical microscopes, transmission microscopes, scanning microscopes, stereoscopic magnifiers, etc.) while subjecting the sample to different loading conditions. This eliminates the need to disassemble the sample for subsequent analysis and enables the correlation of surface phenomena with the mechanical behavior of the material.

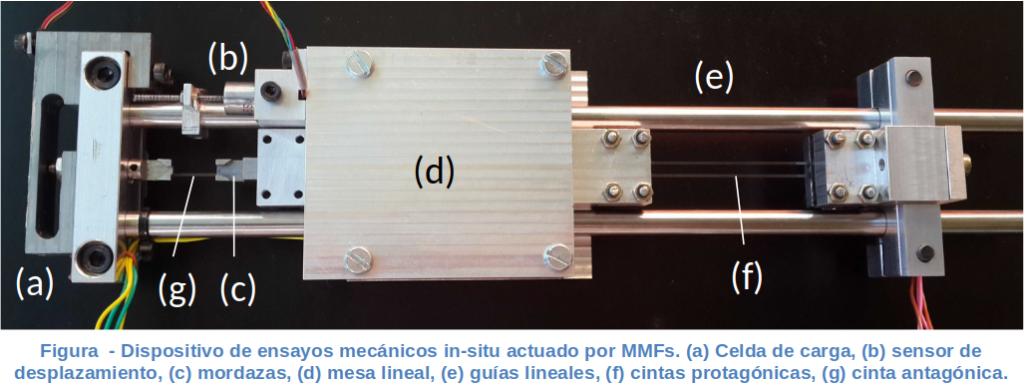

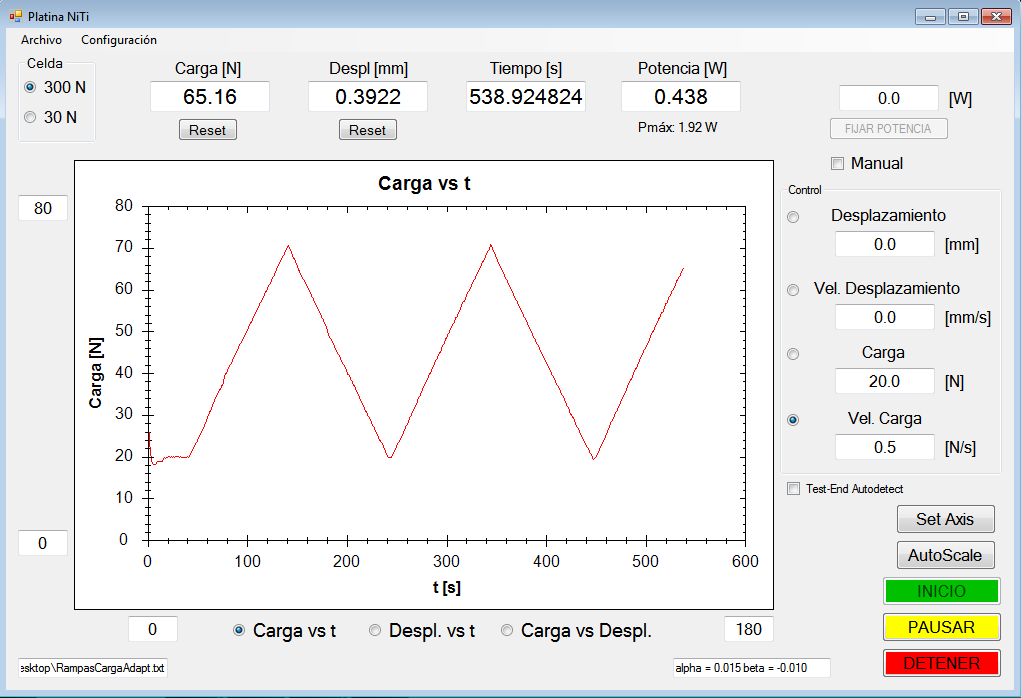

A device capable of conducting such tests, actuated by MMFs, has been developed within the Division, as depicted in the following figure:

This device features MMF strips that work in a protagonist manner (contracting to pull the sample) and others in an antagonistic manner (contracting to compress the sample). This allows for a greater range of operation and response speed of the device. Through adaptive control techniques and dedicated electronics, programs of variable loading and displacement were successfully implemented. The Division is working on new prototypes that may be more compact and capable of achieving a wider range of loads and displacements.

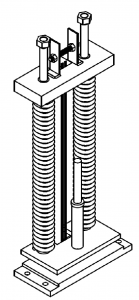

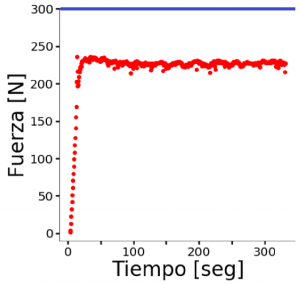

Another interest of the Division is to explore the potential of these materials for the development of independent actuators that can be mounted on various devices. With this goal in mind, an actuator with greater capacity than the previous system has been developed, intended to work in a stationary lever-arm machine. With larger section strips and a reset system using compression springs, this actuator is capable of applying a load of 500 N over a range of 12 mm.

Related Publications

- 2013 — 2014: Cristobal Carracedo, Mechanical Engineering Integrative Project, Balseiro Institute. Title: Development of a device for conducting in-situ mechanical tests on small-sized specimens. Supervisor: A. Yawny, Co-supervisor: L. Ortiz.

- 2018 — 2019: Rodrigo Lopez, Mechanical Engineering Integrative Project, Balseiro Institute. Title: Design of a NiTi shape memory material actuator for a creep-fatigue machine. Supervisor: A. Yawny, Co-supervisor: J. Delmastro.