Metallic Sponges Manufactured by Powder Metallurgy

Metallic sponges offer unique characteristics by combining morphology and performance. They are thermal and electrical conductors and maintain their mechanical properties at higher temperatures than polymers. Unlike ceramic sponges, they have the ability to plastically deform by absorbing energy. If the porosity is open, they are permeable and can be used for applications involving flow or surface exchange.

Cellular materials are widely used today as energy absorbers, that is, to dissipate most of the energy they receive. Generally, the received energy is kinetic and is converted into heat, such as in the absorption of deformation energy from an impact. Conventional metallic cellular materials can absorb a large amount of energy because they compact irreversibly when plastically deformed. We also investigate the use of shape memory alloy sponges. The possibility of using sponges with these properties would extend the use of cellular materials to dynamic solicitations with high levels of reversible deformations.

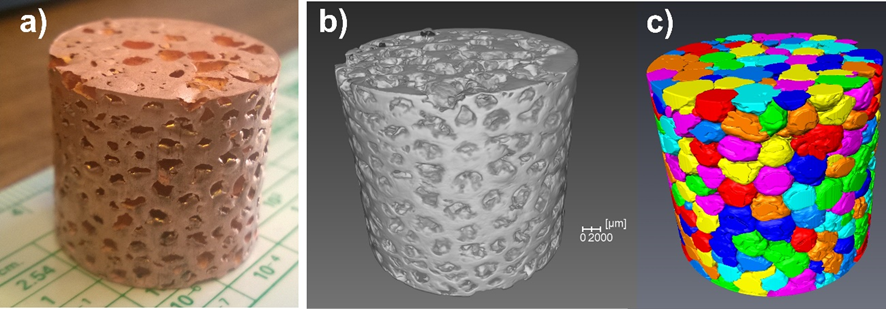

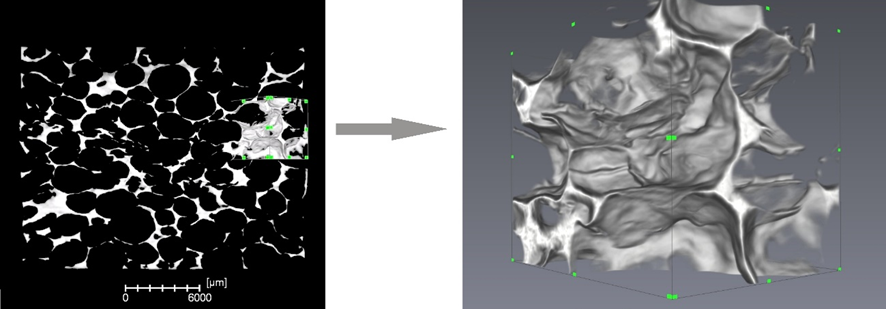

We manufacture sponges using powder metallurgy methods. Currently, we are developing aluminum and copper alloy sponges. For aluminum sponges, foaming agents are used, which are elements that decompose generating a gas when the metal is near its melting point. We are investigating the use of low-cost materials for their fabrication. For copper sponges and their shape memory alloy counterparts, pore formers are employed. Particles of a material are chosen and mixed with the metal powder or metal mixture if it is an alloy. Then it is compacted by pressing and sintered under the appropriate atmosphere to consolidate the sponge. Finally, the pore-forming particles are removed by dissolution or heat treatment, leaving an empty space in their place, thus forming a cell.

We determine the meso and microstructure of the sponges through SEM, x-ray diffraction, and tomography. We also study their mechanical properties and failure modes.

Techniques and Equipment:

- X-ray Diffraction

- Scanning Electron Microscopy (SEM)

- X-ray Microtomography

- Mechanical Testing

Members of the Metals Physics Division

Members of Other Divisions and/or Institutions

Alberto Baruj

José Manuel Espasandín, National Technological University Regional Faculty of Resistencia, within the framework of the PID Project for Consolidation Work Teams.

Highlighted Publications:

“Tomographic characterization of copper cellular bodies fabricated by a powder metallurgy route”, M.T. Malachevsky, G. Bertolino, E. Oliber, C. D’Ovidio, A. Baruj, D. Cuscueta. Materials Research Express 6 (2019) 056531 (https://doi.org/10.1088/2053-1591/ab0310).