Fretting Damage

Fretting is a mechanical condition that occurs when two contacting parts have relative movements of small amplitude, typically in the order of tens of microns. In industrial applications, it is usually caused by vibrations or oscillating loads in one of the contacting components. Once present, it can generate different types of localized damage, such as cracks, wear, and oxidation, which can lead to failures or reduce the service life of the components.

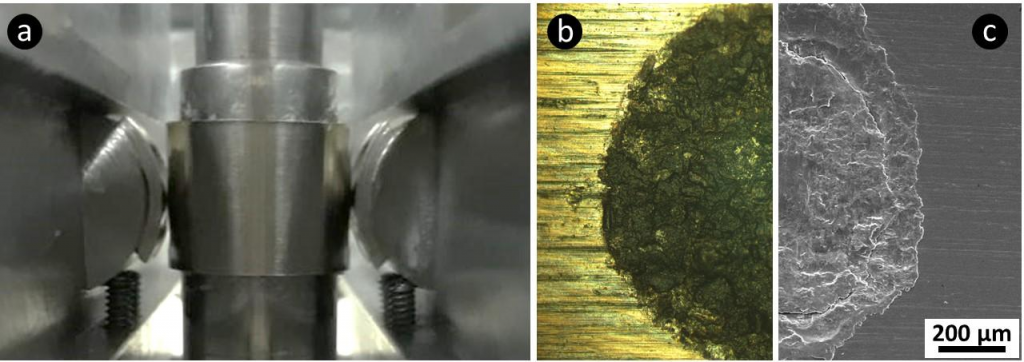

A significant part of the work in this area has focused on the design and manufacture of various experimental devices. Using these devices, most of which are mounted on a servohydraulic test machine, controlled and repeatable experiments have been performed. To characterize the damage in the materials resulting from these tests, different techniques have been used, including optical microscopy, scanning electron microscopy (SEM), transmission electron microscopy (TEM), and optical interferometry profilometry.

Human Resources Training in the Field

In this area, there is a PhD thesis in progress, and as of 2021, 5 professionals have been trained within the Metals Physics Division: a Doctor of Engineering Sciences, two Masters of Engineering, a Mechanical Engineer, and an Electromechanical Engineer.

Although the topic is mainly focused on steam generator tubes, fretting studies within the division have also extended to shape memory materials and hip prosthesis components.

Related Publications

- S. R. Soria, S. Claramonte, and A. Yawny, Evolution of fretting wear with the number of cycles on Inconel 690 steam generator tubes against AISI 420 steel under gross slip conditions, 2021, Tribology International 155:106803, DOI: 10.1016/j.triboint.2020.106803

- S. R. Soria, A. Tolley, and A. Yawny, Running condition and material response fretting maps of incoloy 800 steam generator tubes against AISI 304L pads in air and room temperature, 2019, Tribology International 135, DOI: 10.1016/j.triboint.2019.03.027

- S. R. Soria, A. Tolley, and A. Yawny, Characterization of damage and triboparticles resulting from fretting of Incoloy 800 steam generator tubes against different materials, Wear 390–391, 2017, Pages 198-208, DOI: 10.1016/j.wear.2017.07.022

- S. R. Soria, A. Tolley, and A. Yawny, A study of debris and wear damage resulting from fretting of Incoloy 800 steam generator tubes against AISI Type 304 stainless steel, Wear 368–369, 2016, Pages 219-229, DOI: 10.1016/j.wear.2016.09.022

- S. R. Soria, C. E. Callisaya, H. Soul, S. Claramonte, and A. Yawny, Fretting damage of Ni-rich ultrafine grained NiTi superelastic wires, Journal of the Mechanical Behavior of Biomedical Materials, 2019, 90, 655–664, DOI: 10.1016/j.jmbbm.2018.11.019