Evaluation of Fracture Toughness and Structural Integrity of Engineering Materials and Components

Most engineering components are susceptible to the presence of cracks that can occur during manufacturing or during the service life of the structure, which can eventually lead to unforeseen failures. Given the negative impact associated with these cracks, structural integrity analyses based on fracture mechanics are essential for critical components in various industries.

The research line associated with fracture mechanics comprehensively addresses the experimental evaluation of material fracture toughness (the resistance offered by the material to crack propagation) and its application in structural integrity analyses. The following figures present some of the studies conducted.

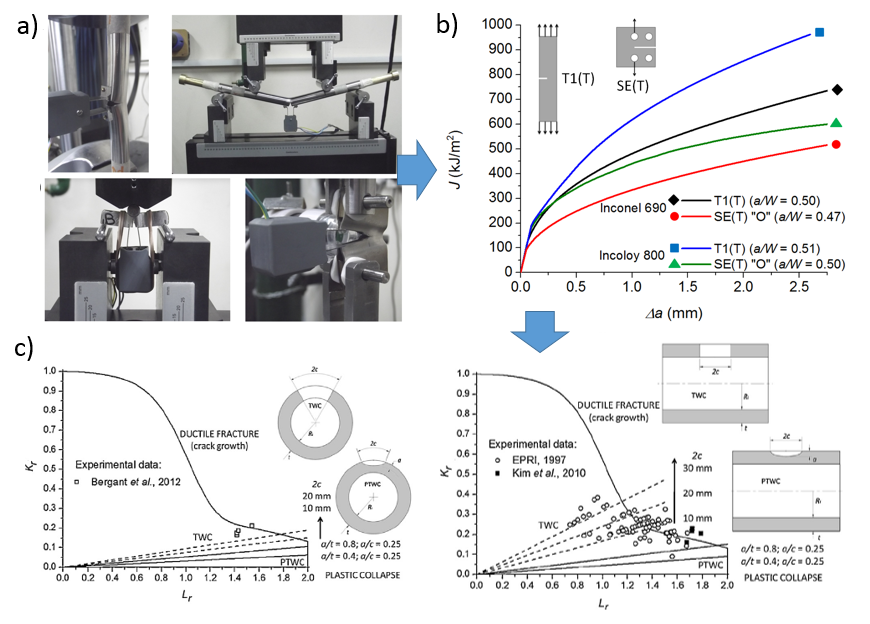

In Figure 1a), fracture toughness tests on nuclear steam generator tubes are observed, carried out on one of the servo-hydraulic machines available in the mechanical properties laboratory. Due to the reduced dimensions of the tubes, this study required the development of innovative methodologies, specimens, and experimental techniques [1-4]. The results obtained were applied to analyses of circumferential and longitudinal cracks in operational tubes, Figures 1b) and 1c) [5-7].

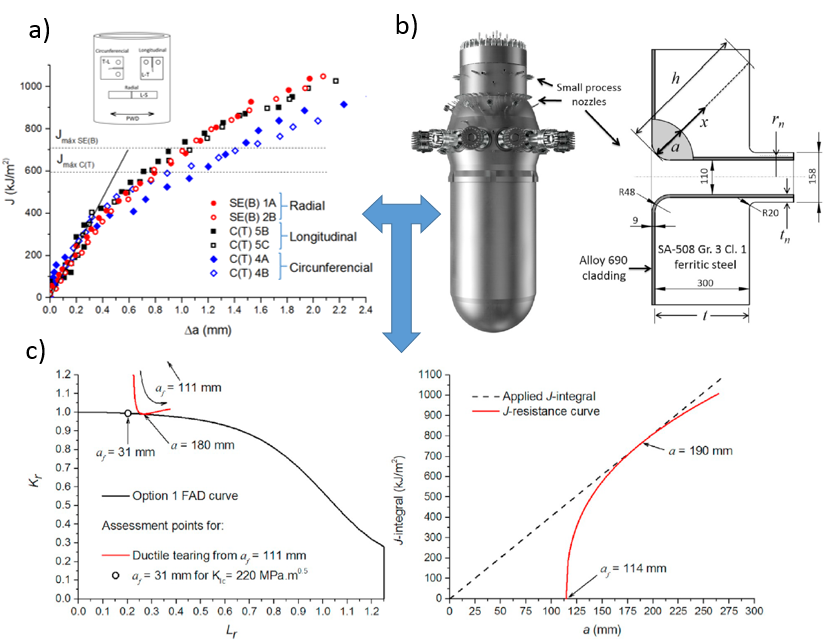

Another line of work is related to the characterization of fracture toughness of ferritic steel SA-508, Figure 2a), which is being used in the construction of the pressure vessel of the CAREM-25 reactor, Figure 2b). The obtained curves are applied in analyses of cracks in process penetrations and dissimilar welds of the pressure vessel, Figure 2b), using different methodologies of elastoplastic fracture mechanics, Figure 2c) [8].

Another current research topic consists of evaluating the fracture toughness in aluminum alloy sheets and their welds obtained by the friction stir welding process. In this study, different toughness parameters obtained from load-displacement records and optical measurements are evaluated to contribute to the development of appropriate characterization techniques for these materials. This research line is carried out in collaboration with the Welding Technology and Mechanical Behavior of Metallic Materials Group at FIUBA.

Research Techniques

- Mechanical tests with servo-hydraulic machines

- Digital image correlation (DIC)

- Scanning electron microscopy (SEM)

Members of Other Divisions and/or Institutions

Juan Perez Ipiña (CONICET)

Highlighted Publications

- M. Bergant, A. Yawny, J. Perez Ipiña, 2017. J-resistance curves for Inconel 690 and Incoloy 800 nuclear steam generators tubes at room temperature and at 300 °C. Journal of Nuclear Materials 486, 298-307. DOI: 10.1016/j.jnucmat.2017.01.040

- M. Bergant, A. Yawny, J. Perez Ipiña, 2016. Experimental determination of J-resistance curves of nuclear steam generator tubes. Engineering Fracture Mechanics 164, 1-18. DOI: 10.1016/j.engfracmech.2016.07.008

- M. Bergant, A. Yawny, J. Perez Ipiña, 2015. Numerical study of the applicability of the η-factor method to J-resistance curve determination of steam generator tubes using non-standard specimens. Engineering Fracture Mechanics 146, 109-120. DOI:10.1016/j.engfracmech.2015.07.059

- M. Bergant, A. Yawny, J. Perez Ipiña, 2012. Estimation procedure of J-resistance curves for through wall cracked steam generator tubes. Procedia Materials Science 1, 273-280. DOI:10.1016/j.mspro.2012.06.037 (reviewed by the Scientific Committee of SAM-CONAMET 2011)

- M. Bergant, A. Yawny, J. Perez Ipiña, 2015. Structural integrity assessments of steam generator tubes using the FAD methodology. Nuclear Engineering and Design 295, 457-467. DOI:10.1016/j.nucengdes.2015.09.022

- M. Bergant, A. Yawny, J. Perez Ipiña, 2020. A comparison of failure assessment diagram options for Inconel 690 and Incoloy 800 nuclear steam generator tubes. Annals of Nuclear Energy 140, 107310. DOI: 10.1016/j.anucene.2020.107310

- M. Bergant, A. Yawny, J. Perez Ipiña, 2015. Failure Assessment Diagram in Structural Integrity Analysis of Steam Generator Tubes. Procedia Material Science 8, 128-138. DOI:10.1016/j.mspro.2015.04.056 (reviewed by the Scientific Committee of SAM-CONAMET 2013)

- M. Bergant, A. Yawny, J. Perez Ipiña, 2020. Damage tolerant analysis of corner cracks in small nozzles process penetration of the CAREM-25 reactor pressure vessel. International Journal of Pressure Vessel and Piping 180, 104036. DOI:10.1016/j.ijpvp.2019.104036